Machine Shop

Fully equipped with CNC Milling and Turning, Wire Eroding, Cylindrical and Surface Grinding, Drilling, Polishing and Welding bay for fabrication. Including Inspection and assembly for Jigs and Fixtures and complete assembly of Special Purpose Machine Tools incorporating Hydraulics and Pneumatics.

- CNC Milling and Turning– 3 axis simultaneous milling or 3+2 axis milling on HAAS CNC mills, Turning up to 2m x 500mm dia

- XYZ CNC Milling Machine

- Surface and Cylindrical Grinding

- Fanuc c600ia High Precision (=/-3um) Wire EDM– 600mm x 400mm x 310mm cut size, 1050 x 775 x 310 mm work piece size, Work pieces up to 1 tonne, Finish to 1.5umRz, Up to 30* taper

- MIG and TIG Welding

- 3m x 2m sealed spray room for high quality painted finishes on all equipment.

- Temperature monitored measurement room

- Sand Blasting

Design Office

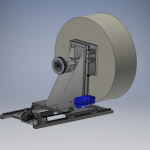

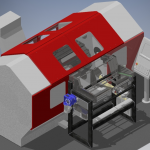

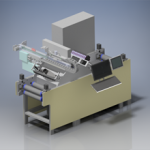

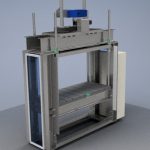

Design engineers running Autodesk Inventor CAD 3D modelling, offering full design services from simple Jigs and fixtures to complete Special Purpose Machine tools, including Hydraulic and Pneumatic control systems designed for specific applications to suit customers requirements.

CAD Design using Autodesk CAD/CAM Products including up to and including 5 axis simultaneous CAM. All of our CAD/CAM work is done by qualified engineers and design draughtsman.

- Machines

Control Systems

Fully equipped Electrical Department with engineers available for the Design and manufacture of Specialised Control Systems (including Electric/Hydraulic Servo) to suit customer’s requirements incorporating PLC and computer control and Business Intelligence integration.

PLC control specialists capable of handling every major PLC brand. Capable of providing support for the largest system including integration of remote monitoring and reporting, robotics and vision systems.